When teams operate independently, it creates communication gaps that can lead to disorder. In contrast, when teams collaborate, they tend to be more efficient.

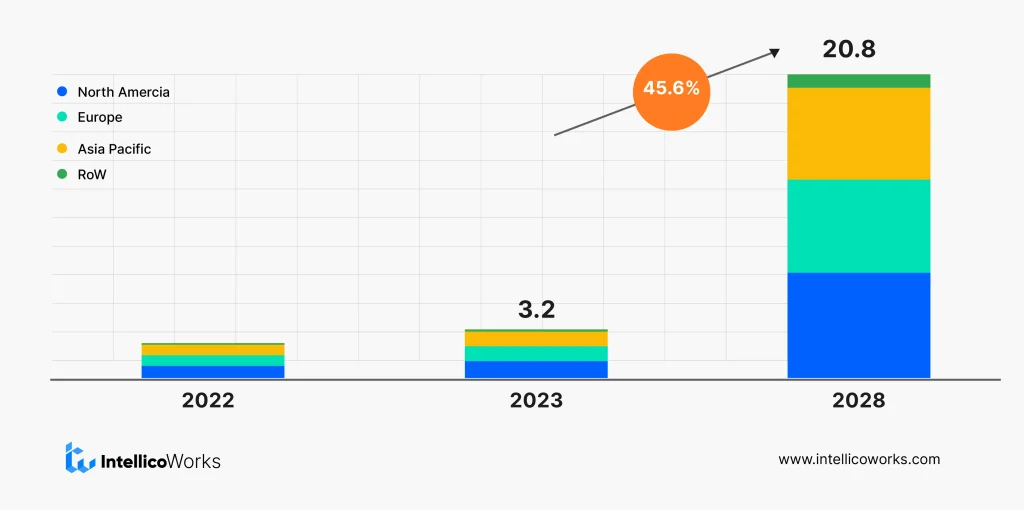

Traditional manufacturing companies lack skilled personnel, supply chain issues and automation challenges. These challenges slow down the sector’s growth. However, AI has the potential to advance the manufacturing industry completely. Manufacturing company processes involve continuous improvement and AI is bringing the concept of “Industry 4.0,” a trend towards greater automation in the massive generation and transmission of data in manufacturing settings. In a report shared by marketsandmarkets, artificial intelligence in manufacturing industry market size is estimated to be USD 3.2 billion in 2023 and is anticipated to reach USD 20.8 billion by 2028. This shows that AI for manufacturing is the future of factories and bigger ones can benefit from it. However, SMBs can get their hands on high-value and low-cost AI solutions

Major factories generate large amounts of data daily. That’s why there are many applications for AI manufacturing. The concept of AI and manufacturing is bringing the use of machine learning solutions and deep learning in manufacturing along with neural networks to streamline manufacturing processes. AI integration in manufacturing companies can change decision-making and data analysis. Predictive analytics are important for any industry mainly in manufacturing. Manufacturing and AI together, companies can easily predict and prevent machine failure. As a result, there will be less chance of downtime in processes. The intersection can bring numerous benefits like reduced waste of raw materials. AI for manufacturing is a marriage as industrial manufacturing requires humans and machines to work together. AI matters for manufacturing because if companies utilize this technology they can optimize processes that lead to cost reduction, safety improvements and supply chain effectiveness.

Traditional manufacturing environments were challenging as it has reduced efficiency, higher operational costs, limited scalability, quality issues, and slow decision-making. AI-driven predictive maintenance and process optimization can help reduce these costs. Scaling operations can be cumbersome and error-prone, and manual quality control processes may not be as precise or consistent. Adopting AI could enhance productivity, reduce costs, and improve production quality and scalability.

In other words, when manufacturing companies use AI in their processes, they can predict maintenance in production. It can schedule maintenance by analyzing possible faults in equipped data that minimize downtime. When the manufacturing supply chain is integrated with AI, it becomes more efficient. By using machine learning algorithms it can estimate demand, control inventory and also simplify the process of logistics. However, robotics 2.0 with AI enables automation that is high-end on assembly lines.

AI-powered QC systems find flaws and guarantee the liability of the final product. Smart manufacturing can use it to monitor processes to make instant adjustments to maximize efficiency and reduce waste.

PwC’s study reveals that Reinforcement Learning can optimize electronic device production by adjusting machine parameters in smart manufacturing, maximizing output, minimizing defects, and enhancing resource utilization.

Overall, AI integration can enhance manufacturing industry processes by promoting innovation, reducing costs, and improvi

The COVID-19 pandemic significantly impacted businesses. Today many are still facing financial and workforce challenges. To mitigate these issues, companies are focusing on artificial intelligence (AI) to apply predictive analytics, create an on-demand labour force, and automate operations. In this section below, we will explore some of the use cases of AI in the manufacturing industry:

Traditional manufacturing involves assembling multiple parts. It compromises strength. However, AI design in manufacturing optimizes structures that use less material. It can also analyze alternative materials for enhanced performance. The most accurate use case of AI manufacturing is generative design. As it provides manufacturers with a tool to explore product and part design. It can unlock more capabilities and possibilities when combined with other technologies like additive manufacturing, multiaxis machining, and injection moulding.

Additive manufacturing quickly prototype products. It also refines designs before implementing them in a real-world production setting using test materials. In injection molding and casting balance of mass and strength plays a vital role. The selection of metals and alloys affects the final production parts and structures.

Generative AI in manufacturing design can mimic original and skeletal shapes. The naturally inspired shapes show the strategy for maintaining strength in an object while reducing the need for material. If you are doing it for industries you will save alot of money. Generative design in manufacturing can also bring benefits like cost-effectiveness. It also helps you work better by benefitting design and manufacturing in so many ways that can be surprising. One of the ai in manufacturing example is:

If you combine it with the new generation of more intelligent, faster, more responsive manufacturing robots in use today, remember, that generative design has had an early impact on optimizing robot end effectors—a device at the end of a robotic arm that interacts with the environment, such as a milling cutter or a paint gun—so robotic cells can carry a more efficient payload.

You may be familiar with 3D printing, it is the same as additive manufacturing. The term additive manufacturing is replaced with 3d printing because it processes products and objects building. This differentiates it from traditional manufacturing where a product is made by cutting away at a block of material. AI can optimize materials dispensation and application as well as optimize the complexity of designing products. It can spot errors, and make them correct by using 3D printing.

A renowned example of additive manufacturing is Blacksmith which uses AI to compare product designs with real-time finished products. This automates fine-tuning of the process and brings the line closer.

Some giants have also implemented it like Rebook, Nike and Adidas. They use 3D printing and create structures for more comfortable shoes.

Industrial robots have been here since 1970. The main drawback of traditional manufacturing is that it is prone to human error while Robotics 2.0 technology helps automate repetitive tasks with accuracy. Robotics 2.0 is a term for industrial robots or manufacturing robots that replace humans. As a result, humans can work on more productive areas of operation. They can be applied in assembly lines, welding, painting, inspection of products, picking loads, placing products, drilling, glass making and also die casting.

When machine learning and manufacturing are used in combination, robots can monitor accuracy and performance in industry processes and get trained to better performance. There are different kinds of applications of robotics. Some have machine visions to help robots achieve and precise mobility in complex environments.

Some are cobots, it is another application that uses machine learning to work safely in the supervision of human workers. It helps complete tasks that cannot be fully automated in less time.

An example of robotics is “Roboy” – a humanoid bot. It is a humanoid robot that aims to test hoped future technologies. He can talk, play music, work, ride a bicycle and also shake hands. Designers take inspiration from human movements to build humanoid robots. They see tendons, joints and muscles closely to replicate them using motors, servos and batteries. These components also include generative design to combine elements and reduce material needs which maintain overall agility.

One of the practical AI use cases in manufacturing is supply chain management. Manufacturing companies have millions and billions of orders, purchases, materials and objects to process. Traditionally it was done manually which resulted in raw materials waste, wrong tracking, and no accurate origin and logistics. Handling these processes manually also is very time-consuming. Companies have started integrating AI into their processes to eliminate the wrong receiving and sending. Machine learning can promote inventory planning, demand forecasting and supply chain management. Traditional supply chain uses ARIMA and exponential smoothing to check demand forecasting. However, AI-powered tools can enable businesses to manage inventory better for the elimination of cash-in-stock and out-of-stock scenarios.

The best example is Walmart – a global retail giant that uses AI in its supply chain to boost customer satisfaction. The retail chain uses ML to evaluate sales data status and inventory levels. This way, the company guarantees that the product is available, out of stock, minimum stock and saves money on the surplus inventory.

AI for manufacturing can be beneficial for production processes to build an intelligent, networked factory ecosystem. It helps evaluate data insights from machinery and interpret maintenance, streamline operations and reduce downtime for IoT sensors.

This ecosystem is very effective for machine-to-machine interaction that allows quick modifications for production schedules mainly for change in demand. AI-linked factories can consume less money with a boost in efficiency, productivity and adaptability in manufacturing ecosystems that are adjective to changing environments.

A notable example of a connected AI factory is General Electric. This company uses the Predix platform to integrate AI with IoT to make better productivity in their manufacturing processes. AI helps GE to stay vigilant about equipment conditions that help make their products smoother when working through data analysis and ML.

The excitement around generative Al in manufacturing comes from building out potential use cases, scaling from creating new designs to ultimately overhauling entire production processes.

The question is, how AI manufacturing growth and potential will be realized? The answer is the facts and figures, manufacturers will be able to tie investments in generative Al to additional revenues with a significant spike of US$4.4 billion from 2026 to 2029. By 2033, revenue added from the use of generative Al in manufacturing will reach US$10.5 billion. Below are some revenue-added growth year by year:

2023 to 2026 (Near Term): Mediocre added revenue growth from 2023 to 2026 as manufacturers adopt current use cases while waiting for more impactful generative Al collaboration with manufacturing software providers.

2026 to 2029(Medium Term): Significant spike in manufacturing added revenue from 2026 to 2029 as high ROI use cases hit the market and are adopted by manufacturers at scale.

2029 to 2033 (Long Term): Growth rates start to cool off in 2029. The added revenue will come from medium, small, and startup manufacturers adopting the use of generative Al to compete in the market.

AI in manufacturing industry can transform the overall process from supply chain to predictive maintenance. However, integrating AI can bring some practical benefits:

The manufacturing industry is high-risk and has reported more than 3,000 major injuries yearly. This is where you can implement cobots or humanoid robots that will do these high-risk jobs for you and reduce unwanted accidents.

AI can reduce operational costs for manufacturing as there are alot of applications like analytics. They can use resources more efficiently to make better forecasts and this reduces inventory costs. Companies that switch their systems to AI will have predictive maintenance that leads to less downtime of maintenance. And this is cost-saving as they don’t have to pay robots. However, they require other maintenance as they are also machines like CAPEX which needs to be weighed against the recurring cost of labor.

Manufacturing industries have a lot of data to analyze. Manufacturers can use IoT sensors to collect large amounts of data and real-time analytics. With this, manufacturers can reach insights sooner before making operations and make rapid and better decisions.

The factories which do not have any human labor are called dark factories. Light may not be important for robots to function and this is a new concept. Only a few experiments of dark factories are operating 100%. These factories can increase over time with the application of AI and other technologies and lead to savings, and end workplace accidents with more production capacity in less time.

Amazon, a global leader in smart product manufacturing and distribution, has been using advanced automation, machine learning, AI, and robotics for over 25 years. They provide AWS comprehensive cloud solutions, enabling manufacturers to optimize production, create new business opportunities, and improve operational efficiencies across the value chain, ensuring high security.

IBM Watson offers a range of AI technology tools and applications to help reduce costs and hurdles in AI adoption. It enables manufacturers to accelerate digital transformation by integrating AI, hybrid cloud, and automation. IBM collaborates with customers to create custom solutions, leveraging existing operational investments and improving key metrics and digital tools.

General Electric (GE), a financial services company, offers services in aircraft engines, power generation, water processing, medical imaging, and industrial products. It diversifies into power, renewable energy, and healthcare sectors. They have implemented a Predix Operations Performance Management solution that helps manufacturers optimize plant performance and throughput, increasing revenue and margins. The technology manages processes and predicts improvement areas, reducing waste and cost while increasing yield and efficiency.

Tesla is developing and deploying autonomy at scale in vehicles, robots, and more. Their main focus is on advanced AI for vision and planning, supported by efficient use of inference hardware. The company is hiring engineers in deep learning, computer vision, motion planning, controls, mechanical, and general software engineering to solve engineering challenges.

They are using neural networks to train deep neural networks on problems ranging from perception to control. The plan is to use core algorithms that will drive the car by creating a high-fidelity representation of the world and planning trajectories. This will accelerate innovation, track performance improvements, and prevent regressions.

The future of Artificial Intelligence in manufacturing is beyond experimentation and hope. Many giants have already implemented AI and robotics in their systems. With the increasing popularity of generative design that is being applied in real-world applications bringing a trend that is called “Industry 4.0”. This is all about designers’ and engineers’ smooth interaction with software.

Moreover, Generative design algorithms can better simulate fluid behavior. It helps engineers create better components for liquid or gaseous environments. A study found that generative design reduced material mass by up to half in the automotive due to the adoption of AI. This is also changing the aerospace, and sporting goods industries. This technology also reduces the barrier to entry for small artisanal manufacturers and encourages innovation, elevating the art and science of manufacturing for the industry as a whole and improving the way things are made. The technology is accelerating Industry 4.0 and advancing materials science, making manufacturing gentler on the planet. In the below picture, some of the machine learning frameworks are mentioned that are used for automation in manufacturing processes.

Artificial intelligence (AI) is revolutionizing various aspects of the manufacturing sector, including supply chain management and predictive maintenance. IntellicoWorks has marked its name in the AI industry as a pioneer in providing AI development services. As a leading AI development company, we build AI for industrial products for data-driven logistics and supply chain management systems for a global manufacturer of heavy construction and mining equipment.

Our teams are well-equipped in AI-powered Robotic Process Automation (RPA) development and analytics. This will help industries automate manual processes, improve supply chain visibility by 60%, and improve operational efficiency by 30%. With the continuous advancements in manufacturing industries, IntellicoWorks creates custom AI/ML solutions that redefine industry standards. Integrate AI and machine learning in your manufacturing processes today transform operations, and thrive in the competitive business environment.

This is definite that AI is the future of manufacturing industries. Results speak, the market for artificial intelligence in manufacturing was pegged at $2.3 billion in 2022 and is anticipated to reach $16.3 billion by 2027, expanding at a CAGR of 47.9% over this period. The stats show the promising future of AI in manufacturing and how it is the right time for businesses to invest in the technology. Businesses can gain significant results with the right partner and the right technology integration. Artificial intelligence in the manufacturing market is all set to unlock efficiency, innovation, and competitiveness in the modern manufacturing landscape.

Drive Innovation in Manufacturing with AI Integration!

Talk to us and let’s build something great together

A Subsidiary of Vaival Technologies, LLC

IntelliCoworks is a leading DevOps, SecOps and DataOps service provider and specializes in delivering tailored solutions using the latest technologies to serve various industries. Our DevOps engineers help companies with the endless process of securing both data and operations.

Ops

Cloud

AI & ML

Copyrights © 2023 byIntellicoworks. All rights reserved.